2021-10-27

According to the material shape, electromagnetic wires can be divided into round wires, flat wires and special-shaped wires. Circular wire is the earliest developed technology. At present, it is still the electromagnetic wire with the largest output and the most widely used. Winding a round wire into a coil will form a gap, resulting in low space utilization, and low motor efficiency and power density. In order to further improve motor efficiency, flat wire motor technology began to get the attention of the industry.

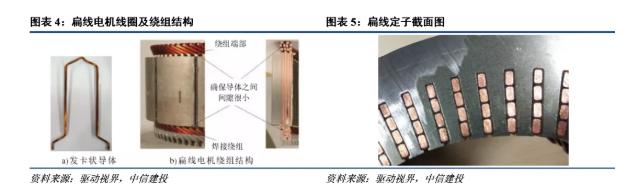

Flat wire motor is a winding technology, which adopts electromagnetic wire with square cross section. When manufacturing the stator assembly, first make the winding into a hairpin shape and thread it into the prefabricated stator slot; Then, the winding is twisted and welded at the other end to form a complete winding. In the square stator section, the square copper wire can completely fill the whole section and improve the utilization efficiency of the copper wire.

Flat wire motor has the advantages of small volume, less materials, high power, high efficiency and less noise. It meets the needs of the development of new energy vehicles and is the inevitable trend of the development of motor industry in the future.

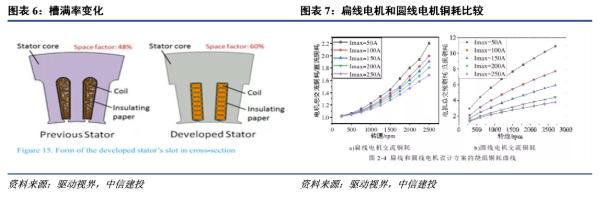

Advantage 1: small size and high power. With the same power, the volume is smaller, the weight is reduced by about 11%, less materials are used and the cost is lower; Or with the same volume, the slot full rate (referring to the proportion of the space occupied by the coil in the slot) is increased, the magnetic field is stronger and the power density is increased. The round wire becomes a flat wire. Theoretically, with the same space, the flat wire motor can reach 70% of the slot full rate, and the filled copper can be increased by 20-30%, resulting in stronger magnetic field strength and increased power.

Advantage 2: better temperature performance. The internal gap is reduced, the contact area between flat wires is increased, the contact between winding and core slot is better, the heat conduction and heat dissipation is better, and the motor performance is improved. The winding temperature rise of flat copper wire motor with the same design is 10% lower than that of round copper wire motor.

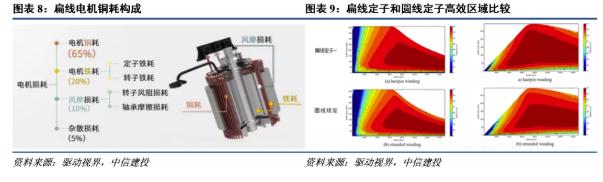

Advantage 3: reduce copper consumption. The maximum efficiency of permanent magnet synchronous motor can reach about 97%. About 3% of motor loss mainly comes from copper consumption, iron consumption, wind loss, etc., of which copper consumption accounts for the largest proportion, about 50%. Flat wire motor can reduce copper consumption by 40% and motor loss by improving copper full rate.

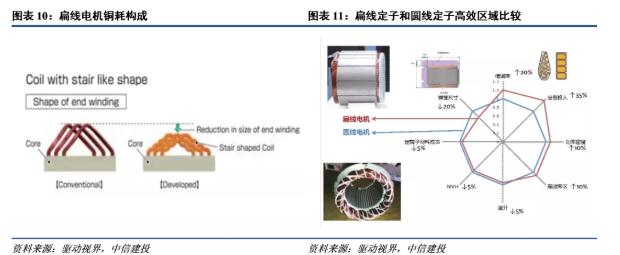

Advantage 4: the average efficiency of the motor will be increased by 1% - 2%, and the full speed efficiency will be increased by 2-3%. The flat wire motor is larger than the round wire motor in the high efficiency area of medium and low speed.

Advantage 5: lower electromagnetic noise. The conductor of flat wire motor has large stress and rigidity, and the armature has better stiffness, which can restrain the armature noise; A relatively small notch size can be taken to effectively reduce the cogging torque and further reduce the electromagnetic noise of the motor.

Advantage 6: the end of the winding is short, saving copper and improving efficiency. In order to avoid damaging the copper wire in processing, the end of the traditional round wire motor usually has a long copper wire. Flat wire motor can make the end smaller during processing. Compared with the circular wire motor, the end size is reduced by 20%, further reducing the volume.

Flat wire motor was first used in high-power industrial motor and high-power generator set, and then extended to the field of vehicles.

The trend of flat wire substitution has been opened in the industry. Flat wire motor was first applied in foreign automobile enterprises. As early as 2007, Chevrolet volanda was equipped with Magna's flat wire motor. In the follow-up, Toyota and Nissan also assembled Japanese electric flat wire motors. Tesla flat wire motor has also begun mass production.

At present, China is also accelerating the research of flat wire technology. SAIC, BYD, BAIC, great wall, Geely, Weilai and other vehicle manufacturers are promoting the use of flat wire motors; Founder motor, Hannah motor and other motor enterprises also began to launch flat wire products.

At present, most manufacturers use hairpin conductor structure to manufacture flat wire motor; Another stator type under development is wave winding, which has the advantages of no solder joints, shortening the end height and saving production cost.

The implementation of Tesla's domestic motor version has driven the continuous improvement of the penetration rate of flat wire motors in the industry. The use of flat wire can improve the motor efficiency and thus the mileage of the whole vehicle. The trend of flat wire motor of new energy vehicles is determined, and both independent brands and joint venture brands are promoting the process of flat wire. This year is the first year of flat wire application. The delivery of Tesla domestic motor version will accelerate the penetration process of flat wire motor in the industry. It is expected that the penetration rate of flat wire motor in new energy models will increase to about 90% by the end of next year.

Network source:https://mp.weixin.qq.com/s/bA18hbUL-ZdGWZERXVWsvg