2021-12-23

1. Program overview

In daily use situation, the load capacity and response time of the hub motor will easily affect our using experience. When there is a heavy load, only the motor which can output enough torque will make a smooth start. If the rated output torque is relatively small, the current of the motor will increase rapidly when carrying heavy loads or climbing hills and other high load situations. Meanwhile, the efficiency will reduce and it will generate a large amount of heat. To protect itself, the power output of the motor have to be limited.

2. Specific implementation plan

In order to improve the output torque and the response speed of the motor, considering the actual design, we can adopt the plan of hub motor combined with deceleration drive. Compared with traditional motor, hub motor has a series of advantage, including less response time, higher accuracy of torque control, can provide both driving and braking torque, can be controlled independently, longer service life and so on.

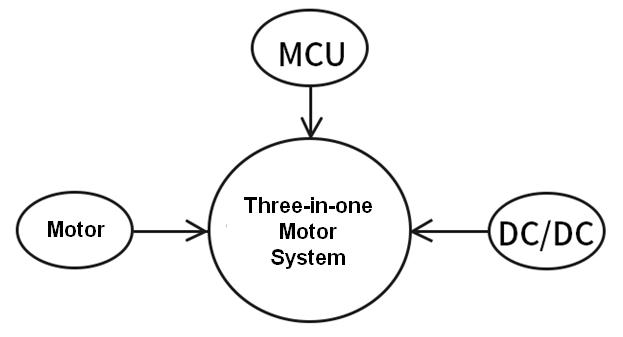

The hub motor is highly integrated. By installing the motor, controller and DCDC devices directly into the driving wheels, it will bring great changes and optimization to the layout of the power system of electric vehicles, including: (1) Improve the system’s efficiency; (2) Higher torque response precision and faster response speed; (3) The arrangement flexibility of the power system is higher, and the vehicle will be more lightweight.

High Performance: Higher power density, Lighter weight, Lower noise, Fewer cost

High integration: Motor, controller and DC/DC device share the same casing

Control strategy: PSPM use FOC vector control

Control system: Safety control and fault diagnosis

hr@inn-mag.com

Plant 3a, phase III, HUanPu International Industrial Park, zone a, comprehensive bonded zone, No. 200, Suhong Middle Road, Suzhou Industrial Park

Copyright © 2020 Suzhou INN-MAG New Energy Technology Co., Ltd. 苏ICP备20020606号-1

Copyright © 2020 Suzhou INN-MAG New Energy Technology Co., Ltd. 苏ICP备20020606号-1