2021-07-07

Introduction

Electrical steel is one of the core magnetic materials of electric vehicle traction motor. However, due to the limited saturated flux density and permeability, the traditional non grain oriented (NGO) silicon steel is gradually difficult to meet the requirements of high power density and high torque density of electric vehicle traction motor. Therefore, after in-depth analysis of magnetic saturation, power loss, thermal conductivity and mechanical properties of traction motor, we propose a new thin anisotropic grain oriented (go) silicon steel which can adapt to high frequency (50hz-400hz) and high torque operation for high-speed (up to 14500 RPM) traction motor. It adopts the combined design of NGO and go steel to avoid transverse low permeability.

Oriented silicon steel is a kind of soft magnetic material, which is used as the magnetic core material of power transformer. It is characterized by obvious Goss texture, i.e. 110 < 001 > preferred crystal orientation. The grain structure of non oriented silicon steel is disordered, mixed with a large number of disordered and different textures. At present, Most of the core components of permanent magnet synchronous motor (PMSM) are laminated with non oriented silicon steel sheets. Therefore, with the development trend of miniaturization and high density of motor system, high saturated flux density and low iron loss of iron core silicon steel materials will become the main requirements in the future. However, due to the low silicon content of NGO silicon steel itself (silicon content is less than 3.5%) and the limitation of metallographic structure, NGO silicon steel will be more and more difficult to meet the design requirements of new motors.

So far, a number of studies have been carried out to solve this problem: Tao F et al. Used amorphous material and NGO silicon steel as iron core to manufacture a 20kW permanent magnet synchronous motor. The volume of the optimized amorphous motor is reduced by 31%, and the power density is increased by 45% under the same power condition. Experiments show that using amorphous material as stator core can greatly improve the power density. Yu-dai. M et al. Proposed a new switched reluctance motor (SRM), whose rotor is designed as a segmented structure of go electrical steel. Compared with the performance of traditional SRM, the output torque of go steel SRM is increased by 4.1%, the efficiency is improved by 2.8%, the eddy current loss is reduced by 7.0%, and the iron loss is reduced by 19.2%. These results prove the superior performance of go steel as iron core in the new generation motor system.

Therefore, a new type of high-speed traction motor with 12 slots and 8 poles concentrated winding is designed. The power is 16kw / 32kw under rated / peak working conditions, and the maximum speed can reach 14500rpm. At present, the research of numerical modeling and experimental results has been completed. The new prototype is being manufactured and can be mass produced in the next few years.

Design of oriented silicon steel stator combined with non oriented silicon steel

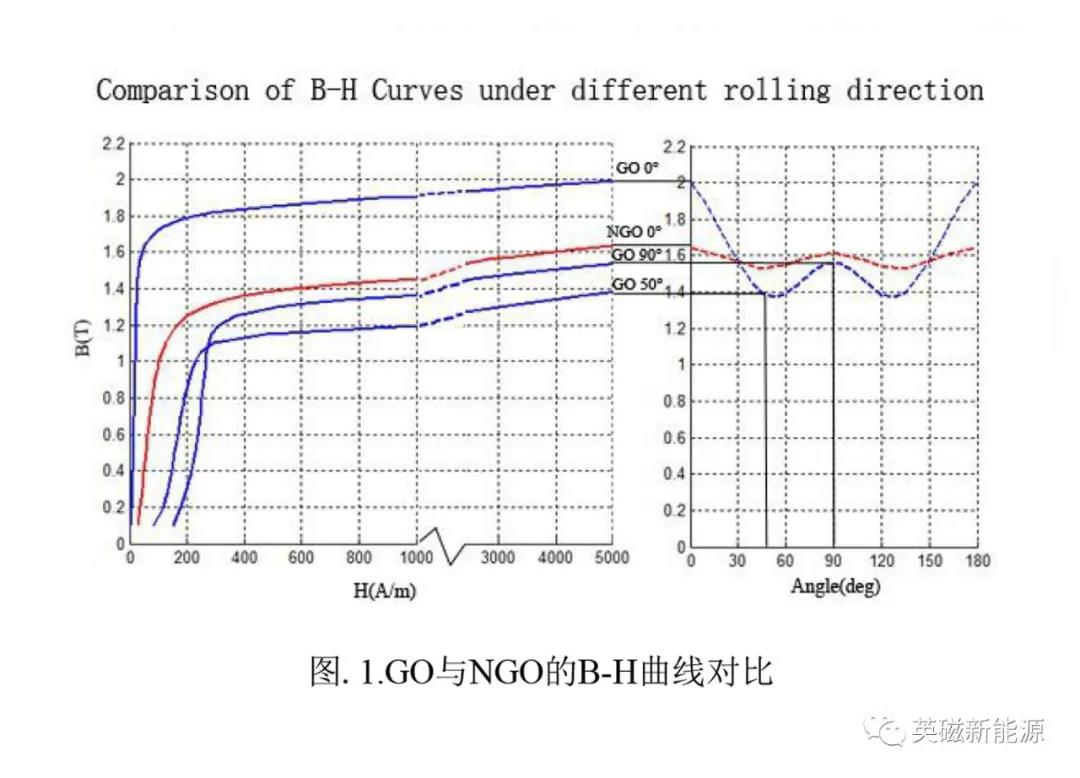

Silicon content of go silicon steel (silicon content 3% - 6.5%) is higher than that of NGO silicon steel, and the grain structure shows strong orientation along the rolling direction. The magnetic properties between 0 ° and 20 ° away from the rolling direction are obviously better than that of NGO. Therefore, the electromagnetic properties of go silicon steel between 40 ° and 60 ° away from the rolling direction are much different from that of NGO silicon steel. In order to verify the conclusion, go and NGO cores have been compared for many times under different current excitation. In the experiment Different b-h-p curves were measured.

Figure 1 shows that the experimental conclusion is consistent with our conclusion above. In the figure, go steel has the worst electromagnetic characteristics and the highest iron loss when it deviates from the rolling direction by 52 °. The saturation flux density at its lowest point is significantly lower than that of NGO silicon steel of the same grade. When the maximum deviation from the rolling angle is 90 degrees, the electromagnetic properties of go silicon steel recover slightly, but it is still lower than that of NGO silicon steel of the same grade.

The next issue will continue to introduce the stator design combined with oriented and non oriented silicon steel and the results of finite element analysis of the new motor. Thank you for watching!